In this post we will be looking at the arrival overview process whilst using pallets.

I will run through an example to satisfy the following business scenario:

You will need to setup the warehouse. To do this use the Warehouse check list.

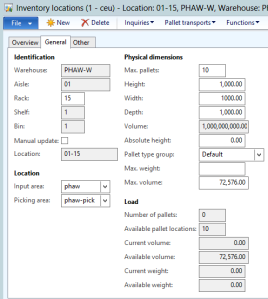

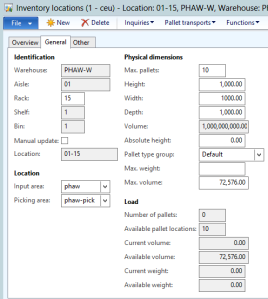

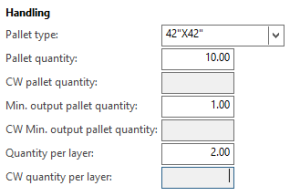

NOTE – Make sure your locations have sufficient space and max pallet quantities to receive the pallets. In this example we are using the contoso pallet 42″x42″ which has a width of 42. you will also need to assign pallet types groups into your locations. See the screen shot below for an example of the setup:

Next you will need to post the product receipts, the Arrival overview screen will allow you to do this task for multiple arrival journals. To do this follow the steps below:

I will run through an example to satisfy the following business scenario:

In our example our warehouse will be using a standard put away methodology whereby a warehouse worker will unload the pallet onto a receiving station, register the stock to this inbound dock and generate the necessary pallet movements within the system for the warehouse staff to complete.The first step in this walk through will be to create our Item, warehouse and our arrival journals.

You will need to setup the warehouse. To do this use the Warehouse check list.

NOTE – Make sure your locations have sufficient space and max pallet quantities to receive the pallets. In this example we are using the contoso pallet 42″x42″ which has a width of 42. you will also need to assign pallet types groups into your locations. See the screen shot below for an example of the setup:

- Open Product information management > Common > Released products

- Click New > Product

- Enter the following:

- Product type – Item

- Product subtype – Product

- Product name – Receive-Test

- Item model group – FIFO (or similar)

- Item group – (any)

- Storage dimension group – (Site, Warehouse, Location and Pallet controlled)

- Tracking dimension group – (Batch physical inventory)

- Stock/Purchase/Sales/BOM unit – (any)

- Purchase/Sales VAT group – (any)

- Click OK.

- Open your item main form, you will need to specify the pallet type defaults and quantities that can be loaded onto that pallet. This will be entered in the ‘Manage inventory’ fast tab, populate the fields below:

- On your item selection the ribbon bar option click Manage inventory > Warehouse > Warehouse item

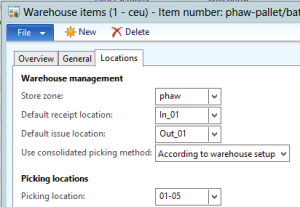

- Create a new line in this form for the warehouse created, then click the tab ‘Locations’ and setup the following information:

- Save your setup and exit the item screen.

- Open Inventory and warehouse management > Setup > Journal names, warehouse management

- Create a new Item arrival and select confirm that the following parameters are ticked:

- Pallet transports – If you have this tick you will need to be using pallet controlled items. This will generate pallet transports.

- Check picking location – If you want to use ’2 stage receive’ i.e. receive the stock onto the inbound dock first then put the stock away to the items default picking location tick this tick box.

- Check bulk location – If you are using pallet controlled items you can select this tick box to manage the bulk location put away. (If your picking location is full AX will allocate a Bulk location to put the pallet away).

- Save the journal name.

- Open Procurement and sourcing > Common > Purchase orders > All purchase orders

- Create a new purchase order for an supplier and select the item created above.

- Confirm this purchase order. Note – You don’t need to confirm for the order to show in the arrival overview. However you will need to confirm if you want to generate the purchase receipt from the arrival overview.

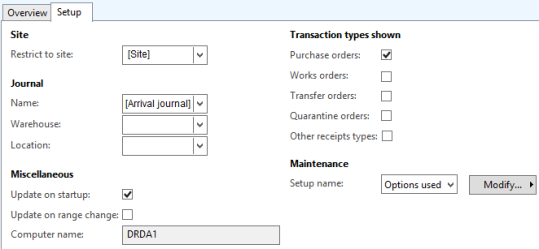

- Open the arrival overview screen Inventory and warehouse management > Periodic > Arrival overview

- Click Setup and select the setup as follows:

- Restrict to site – Set to the site create above

- Journal : Name – Set the arrival journal created above

- Purchase orders – Select the Purchase orders tick box

- Next we can choose to save this setup, to do this click Modify > Save as Select a name and click save.

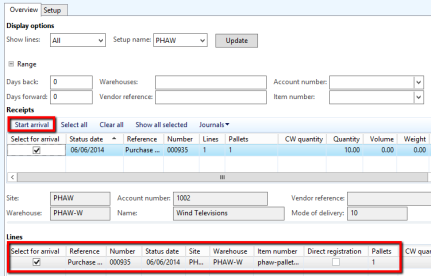

- Navigate back to the overview tab.

- In the Display options section there should be an option called Setup name this should allow you to select the setup selected and other versions you might look to setup.

- Set your date range to pick up the purchase order created.

- Select this purchase order and click Start arrival.

NOTE – The pallet quantity has been calculated at this point

NOTE – The pallet quantity has been calculated at this point - This should bring up an info log detailing the arrival journal created, double clicking this will take you directly to the arrival journal. If you need to find this selection at a later date click Journals > Show arrivals from receipts

- Once in the arrival journal click Lines

- Depending on how many units you ordered you should receive multiple line on this journal (one line for each 10 units representing a pallet each)

- On each line you will need to click Functions > Pallet ID

- This will generate a pallet ID for your lines. Upon entering this information click Post

- This should confirm that the journal has been posted.

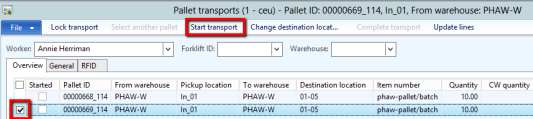

- Navigate to Inventory and warehouse management > Common > Pallet transports

- In this screen you should find the pallet transports required to put your stock away

- Select the line you would like to put away and click ‘Start transport‘

- You can select the work who will then process this transaction etc… Click OK in this screen

- At this point the transport will be in a status of ‘Started‘ you can complete the transport if the location is as expected, if not you can always use the ‘Change destination location‘ function to amend the put away location.

- Clicking Complete transport will physically move the stock from the Inbound location to the destination location in a status of ‘Registered’

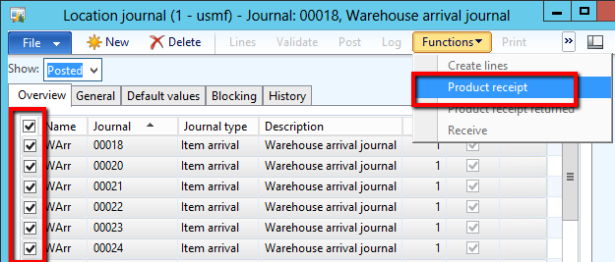

Next you will need to post the product receipts, the Arrival overview screen will allow you to do this task for multiple arrival journals. To do this follow the steps below:

- Open Inventory and warehouse management > Periodic > Arrival overview

- Click Journals > Product receipt ready journal

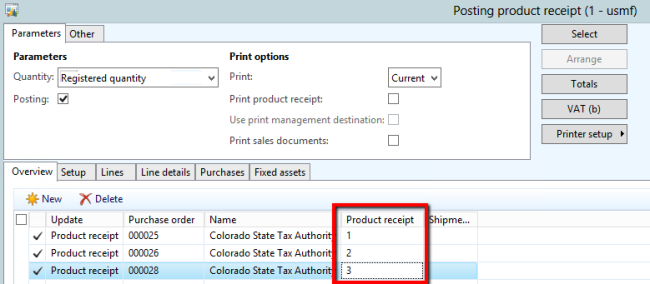

- Select the arrival journals you would like to generate the receipt for and click Functions > Purchase receipt

- The purchase receipt screen will then be loaded and present the user

with the opportunity to enter the different purchase receipts:

- Click OK to post these receipts.

No comments:

Post a Comment